Highest rank ever!

A lot of people ask me how book sales are going, so I thought I’d share a little bit about what I know. You would this this would be an easy thing to track, but you would be wrong.

As of December 29th, 2010 – about 4 weeks after the book was released – a contact of mine at McGraw-Hill told me they had sold 2,335 units. That number sounded good to me! But the trick is those don’t really count as sold, because those are all the units that are sitting in warehouses of the resellers (Amazon, Barnes & Noble, etc) and could potentially be returned. The “sell-through” number is the real indicator how how many customers have books in hand. That same day, McGraw-Hill told me the sell-through was 75-100 copies a week through the major resellers (mostly Amazon).

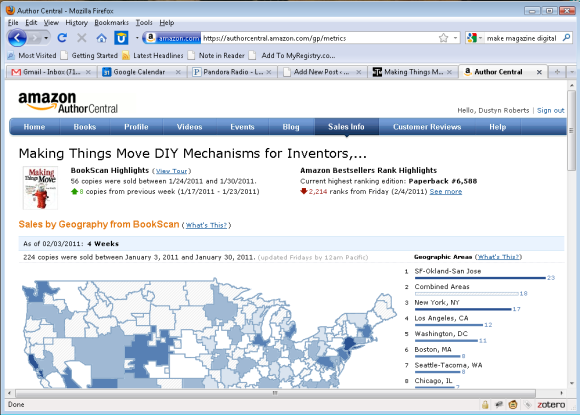

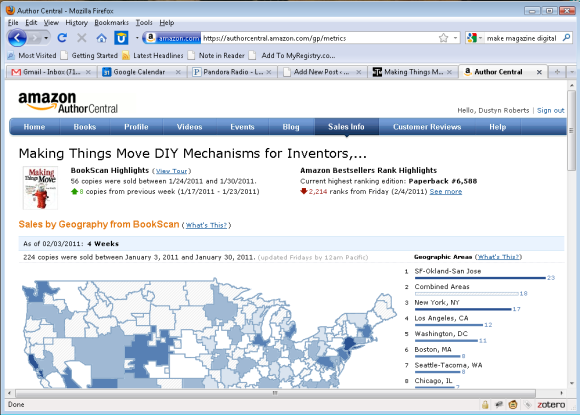

I was craving better data, and luckily Amazon answered my call with access to a new Sales Info tab within their site. Any author that has a book sold on Amazon has access to “Author Central” where you can change the description, upload an image of yourself, and now track sales:

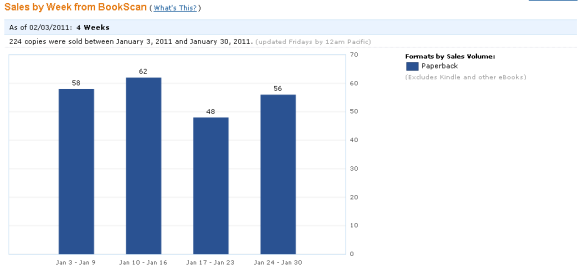

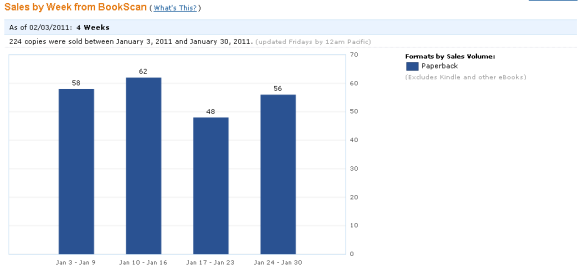

Another trick in the numbers is that this data is provided by Nielsen BookScan and includes only approximately 75% of all retail print book sales in the U.S. Previously this data was only available to publishers, so this is a huge step forward. However, this number does not include international sales or eBook sales. As of January 7, 2011 McGraw-Hill told me there were 497 Kindle sales. That’s a pretty good number too, but that’s the only eBook format they have data on – no idea how many Nook Book or other downloads there have been.

Within the BookScan data, I can see sales by geographical region (above), and totals per week (below).

Now Amazon itself doesn’t track number of books sold (or at least they don’t give access to that data) but they do track sales rank for both paperback and Kindle versions. But although this rank gets updated hourly, the only data point that gets saved is the sales rank around midnight Pacific Time.

To me it seems silly to go to the trouble of calculating a sales rank every hour, then just losing all that valuable data! I’ve mentioned this a few times in emails to them, but haven’t seen any changes. It would be AMAZING to have more detailed data to track cause and effect of marketing efforts without refreshing my book’s page every hour. For example – what’s the best time to put up a blog post, tweet, or Facebook update in terms of driving sales rank?

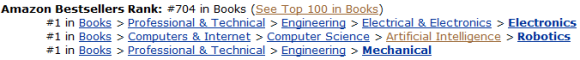

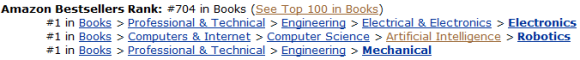

Another thing that gets updated hourly but they don’t track at all is sales rank within category. My book has ranged from #1 to unlisted in a few different categories, but I have no access to that history at all.

I realize Amazon does have an API, and there may be some way for me to get all this data collected and stored, but I have no idea how that works – Leave a comment if you do! I would love to post a real time (updated hourly) graph of sales rank on this site but will have to settle for the limited-but-better-than-nothing data Amazon provides for now.

Thanks to everyone who bought my book and helped with these numbers! And finally, I would LOVE if you left your honest opinion in a review on Amazon. Whether you’re a middle school student or a college professor, your opinion is valuable and I would love to hear it.