I’ve been invited by Aki Sasamoto, one of the Whitney Biennial artists, to participate in a kind of workshop at the Whitney on April 16th. She’s a co-director and founding member of the NYC non-profit Culture Push along with my student Arturo Vidich. The event is based on her past DOING workshops, which bring together a small group of 10 professionals to share a little bit about each one’s practice with each other. As she says, the goal of this workshop is to introduce all the participants to other ways of thinking through doing. We’re starting with a private event on April 4th for these 10 people a week before the Whitney event. Each person prepares an activity that can be executed in 30-60 minutes by the other participants. The list of participants hale from a wide variety of backgrounds:

Matthew Bauder (Composer/Saxophonist)

Serra Victoria Bothwell Fels (Metalsmith/Designer)

Deborah Gorman (Chef)

George W. Hart (Mathematician)

Tim Hyde (Artist)

Yvone Meier (Choreographer)

Saul Melman (Artist/Doctor)

Igal Nassima (Programmer)

Ashley Rawlings (Editor, writer and art historian)

…and myself.

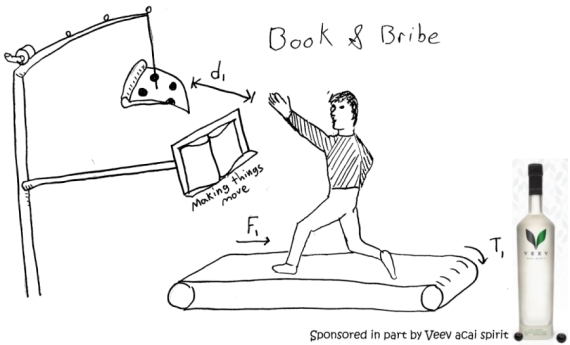

The event at the Whitney is open to the public and will accommodate about 100 people that get to rotate through 6 different activities. Our 30-60 minute activities from April 4th will be distilled into 20 minute mini-workshops in which each participant will get to execute or practice a skill that deals with the leader’s profession. After some discussion with Aki, we settled on a version of an assignment I give my students every year: mousetrap powered cars.

There are more constraints on this project than I give my students on their assignment…

1) We figured designing 2 different versions would add some spice to the events. The two versions will be similar with one important difference – for example, wheel size – so the effect is noticeable.

2) Between the 10 person workshop and the event at the Whitney with 2 groups of 20, I need to come up with ~60 mousetrap car kits (which leaves a few for spare parts/demo models). This means I can’t just cobble together parts I have lying around, but need to identify parts that I can buy 60 of. Preferably locally sourced so I don’t have to pay for/wait for shipping. These kits will have a second life as a project in my book, so this exercise will be a good test.

3) I have an approximate budget of $200. $200/60 = $3.33 per car. The mousetraps already cost $1 each, so that’s $2.33 left for everything else.

4) The kits need to pack flat, or close to it, so it’s easy enough for me to transport 60 of them by myself without anything breaking.

5) The kits must assemble and be raced within 20 minutes.

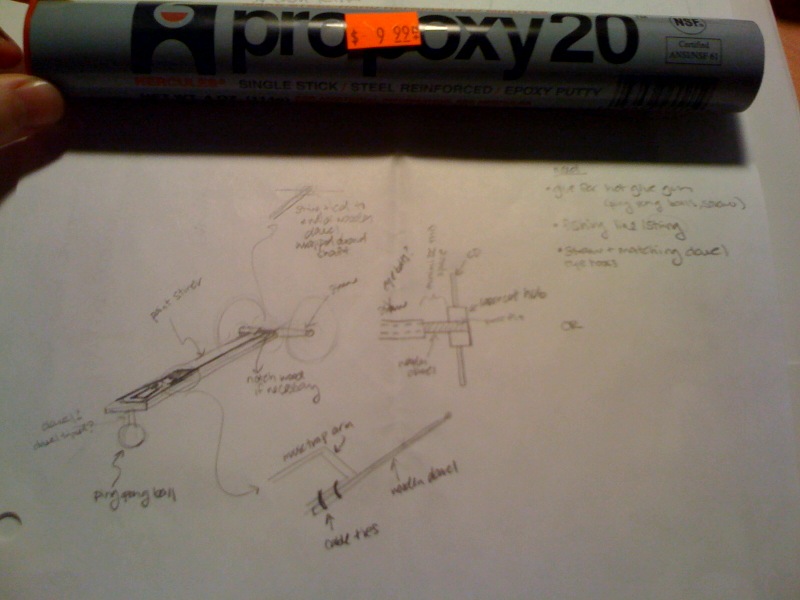

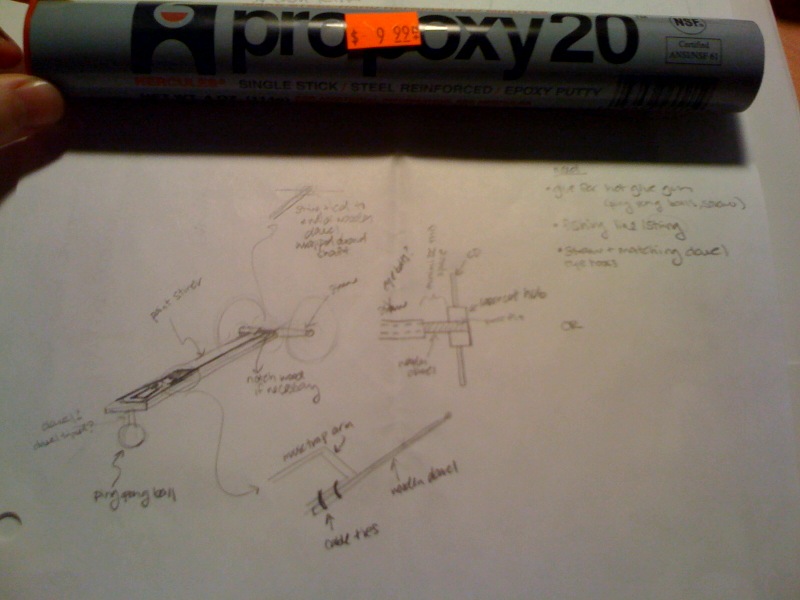

So, I set out to the hardware store to get some basic supplies and start trying to build the simplest mousetrap car possible. I got 60 mousetrap cars, 8 1/4″ diameter wooden dowels, eye bolts that fit the dowels, plumber’s putty, and fishing line. I asked to buy 60 of those wooden paint stirring sticks to use as the car base, and they threw them in for free – thanks Artie’s! Then I sketched out some quick ideas:

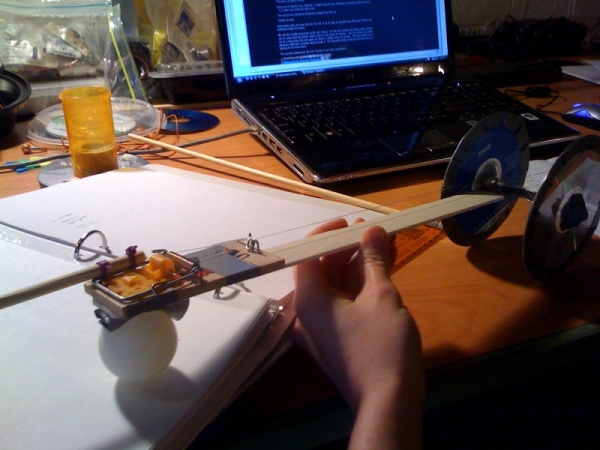

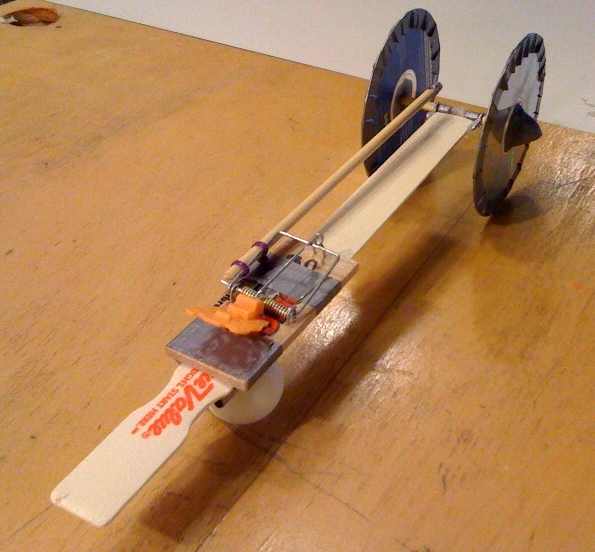

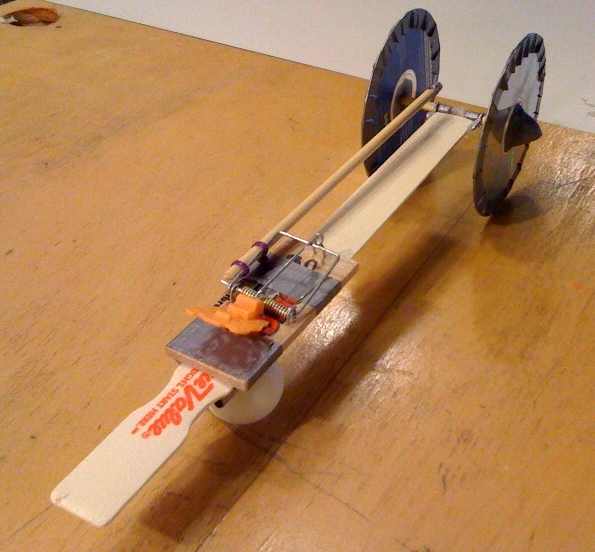

Two students of mine, Russ and Kody, built a very minimalist mousetrap racer for their class assignment. Inspired by this idea, I set out to simplify the design even further: use the ping pong ball as a caster and not a rotating wheel, and stick it to the bottom of the mousetrap instead of using an extension. I used some old CDs for wheels, and plumber’s putty to hold the wooden dowels in place in the center of the CDs. This putty is actually a two part glue with the consistency of clay – if you get the stick type, all you do is twist off a piece, mush it around in your fingers until the two different colors of “clay” blend into one, then stick it on anything. In 10-20 minutes it hardens like steel and you can drill it, sand, it, and treat it more or less like metal. Amazing stuff. You can see the putty on the end of the axle below, along with the eye-bolts that were screwed right into the mousetrap base to hold the wooden dowel axle.

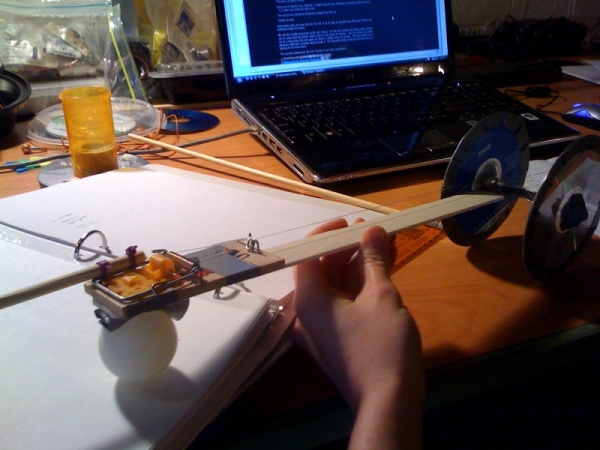

I figured this first car would just flip over, but I wanted to see how few parts I could use. So I stuck the ping pong ball on the end of the mousetrap with some duct tape, and tied some fishing line to the moustrap arm and the axle. Then I wound up the fishing line around the axle by spinning the wheels, set the mousetrap, and watched mousetrapcar v1.0 fail. As I figured, the axle of the car was too close to the mousetrap spring axis, so the force was so high it just peeled out and since there was no extended base to support it, it kind of flipped over. I could add some foam or rubber for traction on the edge of the CD wheels, but I wasn’t confident that was the best solution. So I opted for using the paint stirring sticks as a base to lengthen the distance between the car axis and the mousetrap spring axis, therefore decreasing the spinning force on the wheels, and put some duct tape on the CD edges to increase friction just a little…

Mousetrapcar v1.1 worked – sort of. The eye-bolts can’t screw right into the paint sticks because they are too thin and just split, so I tried duct tape first but hot glue worked much better. Also, the fishing line got a little caught up in the eye-bolts, and the car was reeeeeeaaaaallly slow. So, for the mousetrapcar v1.2, I made two changes:

1) Contain the fishing line with duct tape inside the eye-bolts, so it doesn’t get tangled. I also did some calculations to see exactly how much line I would need, so I didn’t have extra line that would contribute to tangling and not get used.

2) Move the mousetrap closer to the wheel axis (and cut the wooden dowel arm to match) to increase the force a little, to make the car go faster.

Mousetrapcar v1.2 works pretty well, but is still too slow and gets stuck easily even on the smooth table at Eyebeam I was using for tests. So my next step when I get back to Eyebeam is to move the mousetrap even closer to the wheel axis to increase the pull force and make the car go faster and handle a bumpy floor better. I also need to laser cut hubs for the wheels for the Whitney version because the plumber’s putty takes too long to harden. I have enough old CD’s for ~20 mousetrap cars, so that will be version 1, and then I’ll just laser cut wheels that fit right onto the wooden dowels for version 2.

Continued here…